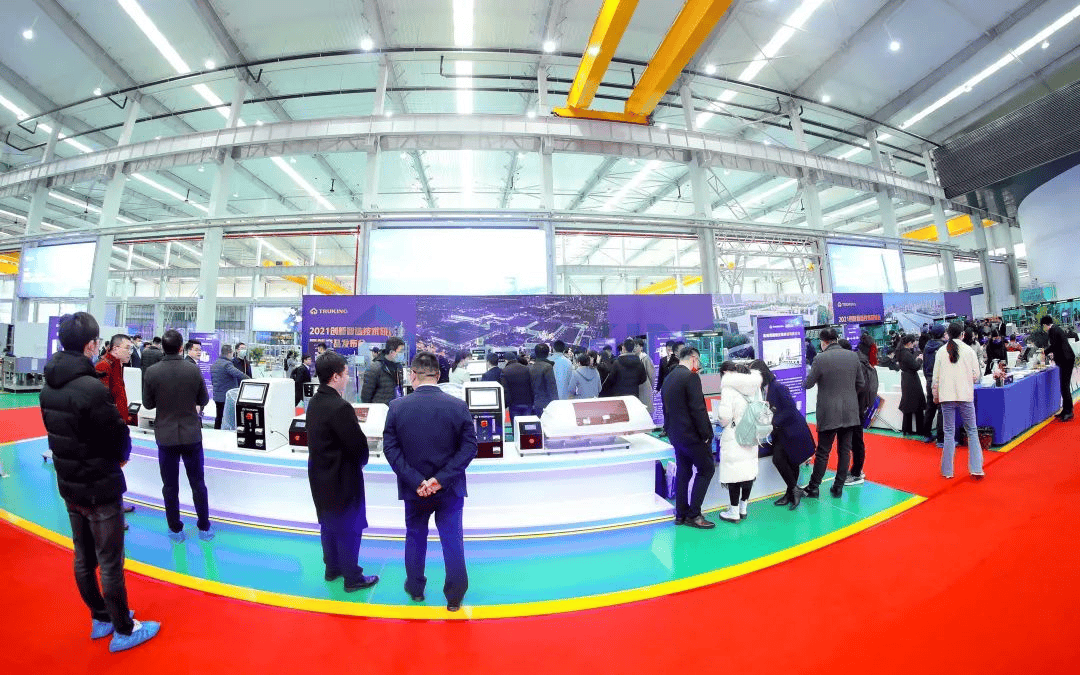

TRUKING held the 2021 Innovative Intelligent Manufacturing Technical Seminar and Product Launch on 18th December. More than 400 professionals from various fields such as the biopharmaceutical industry, and experts from relevant authorities such as the drug regulatory agencies came over to attend this seminar. We held the Sterile Preparation Forum, Bioengineering Forum, and Innovative Packaging Forum. Meantime, the seminar was also a showcase for nearly 20 products of Truking, which are the fruits of our latest technical innovations and iterative upgrade. The release of wave bioreactor, full-automatic microcarrier suspension culture bioreactor, basket bioreactor, single-use mixing system and some other types of front-end process equipment has witnessed Truking’s great leap forward in biopharmaceutical process and equipment.

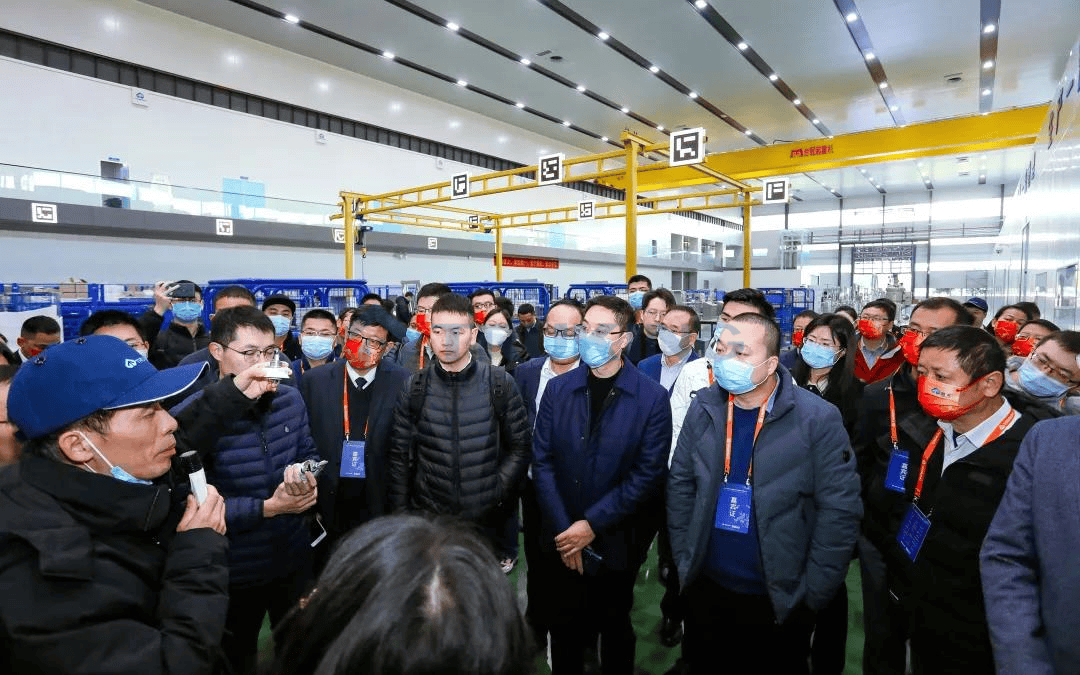

Attendees were visiting Truking Technology Industrial Park

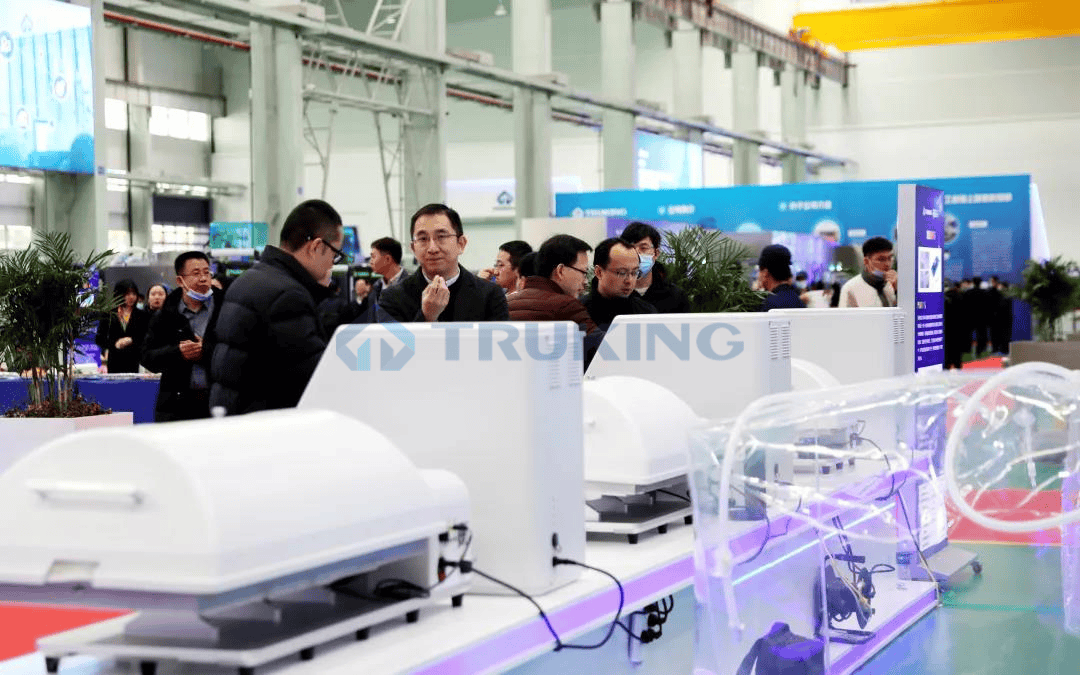

Nearly 20 innovative products were unveiled in the seminar

Among the chemical medicine, bulk drug, Chinese patent medicine, biological medicine and some other pharmaceutical markets across the world, the biological medicine has developed most rapidly. Its clear development trend indicates that it will become the largest segment under the global pharmaceutical market, and will surpass chemical medicine and other segments in terms of the market size. The global outbreak of COVID-19 epidemic has made COVID-19 vaccines a well-known biological medicine. The achievements of China Biotechnology Co., Ltd. of China National Pharmaceutical Group Corporation and other enterprises in the research and development of COVID-19 vaccines have shown China’s strength in biopharmacy to the world. Under this background, TRUKING, a leading enterprise in pharmaceutical equipment, cooperates with those main Chinese vaccine enterprises, and the mass production of COVID-19 vaccines is also a testimony of China’s strength in the biopharmaceutical process and equipment.

TRUKING's upstream equipment, such as biological raw liquid preparation and purification equipment, as well as midstream and downstream equipment, such as intelligent aseptic packaging, intelligent detection and intelligent subpackaging, has played an important role in the mass production of COVID-19 vaccines. It is a perfect demonstration of What Truking has achieved with its research, development and manufacturing technologies and its strategic plan in biopharmaceutical process and equipment. Through the strategies of internal growth, external mergers and acquisitions, as well as effective integration, TRUKING has rapidly promoted its development of upstream process and equipment in the biopharmaceutical field. Many a product, such as single-use bioreactor, single-use liquid preparation system, ultrafiltration chromatographic purification, stainless steel reactor and packing, has been available, and a variety of products were unveiled at this product launch.

Chen Xin, a general manager at Truking SUT Biotechnology (Changsha) Co., Ltd, was speaking to news media during the product launch

The particularly eye-catching wave bioreactor at this product launch can be applied in cell therapy, antibody drug seed expansion and vaccine production. The controllable linear oscillation technology brings excellent effects in mixing and gas mass transfer, and the customizable single-use bioreactor bag which is pre-sterilized with radiation effectively guarantees the aseptic environment of the whole process and reduces the risk of contamination. As a general-purpose platform for suspension cell and adherent cell culture, the wave bioreactor features high reliability in the drug research, process development and commercial production. This wave bioreactor comes from Truking SUT Biotechnology (Changsha) Co., Ltd, a holding subsidiary of TRUKING, where a group of top talents in biopharmaceutical field display their abilities in their job. During the launch, some biopharmaceutical manufacturing products and consumables developed by Truking SUT were also exhibited, such as cell culture bags.

For TRUKING SUT’s single-use soft bags, the standardized and customized 2D and 3D design solutions are available. These bags can be used to store and transfer liquid or powder in the biopharmaceutical process, replacing traditional glass bottles, stainless steel containers and hard plastic bottle. The complete verifications of biocompatibility and chemical compatibility, as well as the usage risk assessment data package provided by the international expert team, convince intended users to switch to TRUKING SUT’s single-use products, and ensures the safety, reliability, and compliance during the usage process. In order to create a bridge between Truking SUT and the cutting-edge biopharmaceutical resources, TRUKING SUT Biotechnology (Changsha) Co., Ltd. has established a subsidiary in Shanghai and the workshop is under construction, which will be used for the development and production of the biopharmaceutical manufacturing products, such as single-use bioreactor, liquid preparation bag, liquid storage bag and membrane materials. Besides, a large-scale workshop for manufacturing single-use systems and consumables in TRUKING Technology Industrial Park in Ningxiang, Hunan, will start construction next year.

Users were visiting TRUKING’s Central Workshop to see our offerings

The production-grade ultrafiltration system, automatic chromatographic column, and production-grade chromatographic system exhibited at this product launch come from Truking Ingenuity Biotechnology(ChangSha) Co. Ltd. As a holding subsidiary of Truking, Truking Ingenuity provides integrated separation and purification solutions and services for biopharmaceutical enterprises all over the world. Its products are widely used in the production of monoclonal antibodies, insulin, blood products, vaccines, recombinant proteins and other biological drugs. Beside, Truking expands it business in the packing field by the establishment of Truking Microshpere Biotechnology (ChangSha) Co.Ltd., another holding subsidiary of Truking. Our microshpere products include natural polysaccharide microspheres, silica gel microspheres, polymer microspheres, inorganic microspheres, etc.. Among them, our main product is agarose microspheres, which is mainly used in the biomacromolecular medicines. Truking Technology is also actively planning the development of biopharmaceutical manufacturing products such as culture media and packaging materials.

With the rapid development of biopharmaceutical industry and vast market demand, the contribution of the products and services in the biopharmaceutical industry to the total sales revenue has grown rapidly. "....especially the midstream and downstream equipment made by Truking. The technical levels and operational performances have been fully validated by the mass production of high-end biological medicines such as COVID-19 vaccines. Meantime, Truking is also actively planning the development of the upstream process and equipment in the biopharmaceutical industry. For example, stainless steel reactor, raw liquid preparation, ultrafiltration chromatographic purification, single-use products, packing and other products have been gradually improved. This product launch is a showcase for the fruits of our development," said Tang Yue, the chairman and president of Truking Technology, "It is a well-established strategy for Truking Technology to focus on the development of biopharmaceutical equipment, especially the upstream equipment, consumables and accessories.”

A wide range of brand new products made their debut in this product launch, including the intelligent counting line for bottled medicines, 12-column liquid strip packaging machine, as well as strip package weighing and aligning machine. The intelligent counting line for bottled medicines is mainly used for the packaging line containing the filling of tablets, pills, hard and soft capsules and other kinds of solid medicine grains, the stuffing of drying agent, as well as cap rotation, aluminum foil sealing, detection and labelling. The stable capacity of the whole line can reach up to 220 bottles per minute, and it can be widely used in medicines, health products, food and other industries. This is a key step for Truking in expanding its business in the solid preparation production equipment. With its further application and development, an effective connection with the relevant solid preparation production equipment of Romaco can be achieved, thus producing synergy effects in terms of the product and market.

The 12-column liquid strip packaging machine applies to the filling and sealing of medicines, all kinds of liquid in health industry and pastes. It can be installed after the fluid preparation line, and before the strip package weigher, aligner, sterilization system, cartoning machine, case packer and stacker, forming a fully automated production line which combines fluid preparation, primary packaging and secondary packaging together. The strip package weighing and aligning machine is mainly designed for the on-line check weighing of strip packages from multi-column strip packaging machine, and aligning strip packages by specifications before they enter into the downstream packaging process. The efficient online check weighing of individual liquid and solid strip package, and automatic alignment by specifications can verify the filling accuracy of strip packages. With such kinds of strip package equipment, Truking has succeeded in extending its business in the new field, and they further diversify the product line and link the upstream process and downstream process.

Another eye-catching product is the high-performance robotic PFS inspection system. Its excellent performance in the mass production of COVID-19 vaccines in China has demonstrated that Truking's product has been in a leading position. To meet the user needs, based on the strong research, development, design, processing and manufacturing capabilities, and with the cutting-edge AI visual inspection technology, the de-nesting, lamp inspection and re-nesting can be automated.

Li Shujie, deputy director of Central Technology Institute of Truking Technology, was speaking to news media during the product launch

With upgraded technical levels, operational performances and appearances, a new generation of vial filling and stoppering machine, ampoule filling and sealing machine, ultra-high speed PFS production system, blister packaging machine, full-automatic horizontal continuous cartoning machine, full-servo three-dimensional wrapping machine, and automatic vertical loading and stacking machine were presented on this product launch. “Many products of Truking can be used as a substitute for the imported ones. Truking will continue to invest more to keep a favorable position in sterile packaging, detection and subpackaging products, and build a team for developing intelligent and innovative pharmaceutical equipment. The recent Central Economic Working Conference called for a further consolidation of the role of enterprises as main players of independent innovation. We will continue to increase our investment in innovation, and try to make new breakthroughs in pharmaceutical equipment in China.”said Tang.

Three professional forums were held at the same time

Afternoon, 18th Dec.

Sterile Preparation Forum, Bioengineering Forum, and Innovative Packaging Forum

Three professional technical forums