400-9988-900

400-9988-900

400-9988-900

400-9988-900

Emulsion injections play a vital role in clinical applications, including fat emulsions, total parenteral nutrition (TPN), and anesthetics like propofol. Despite their strong therapeutic effects, their inherently opaque milky appearance makes them one of the most challenging dosage forms to inspect.

Inspection Challenges: Detecting Defects Through a Milky Haze

Compared to clear aqueous injections, emulsions present multiple unique challenges:

Technical Solution: Integrating Optics and AI to Enable Reliable Emulsion Inspection

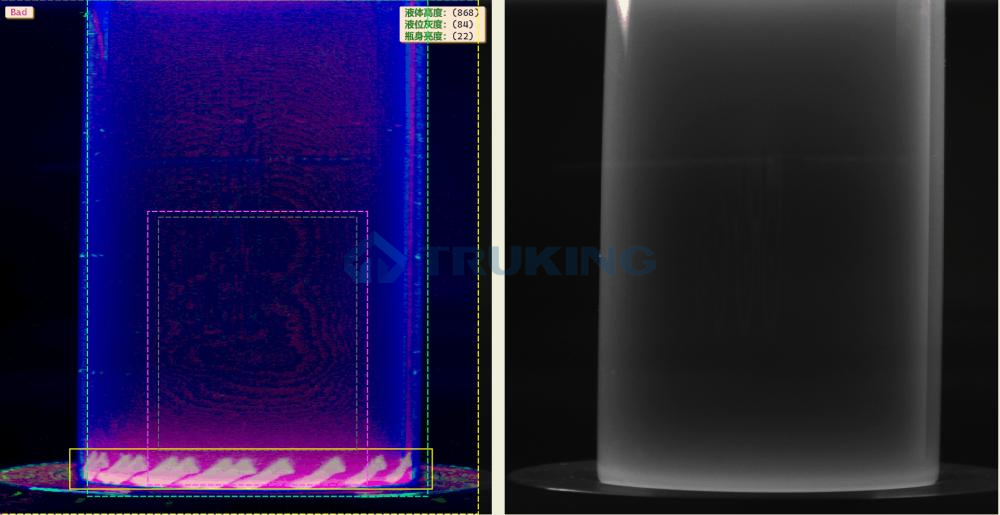

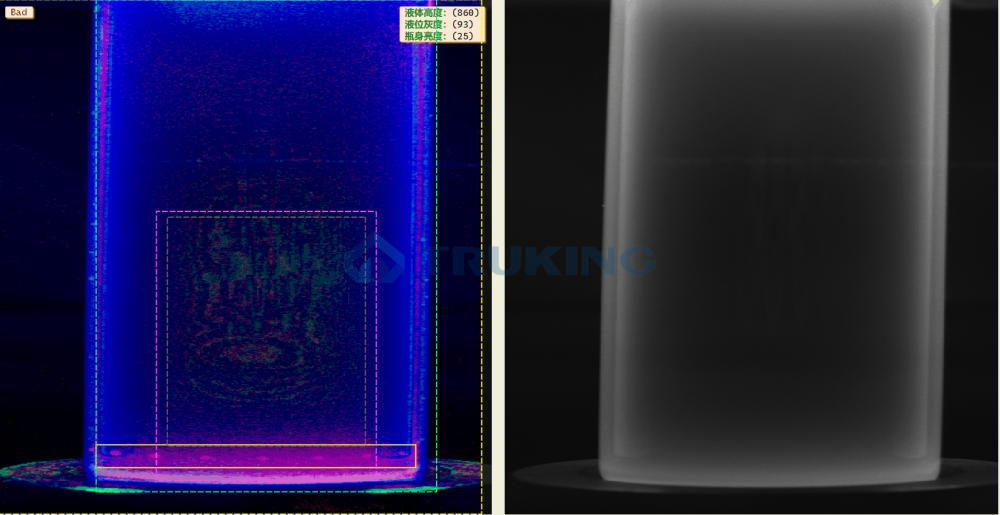

To overcome opacity and interference challenges, Truking has developed a complete solution combining optical acquisition with intelligent recognition to detect and classify multiple types of defects in emulsion products.

Our system includes:

Together, these optical and AI technologies enable reliable detection of various defects including black spots, glass shards, oil droplets, and hair.

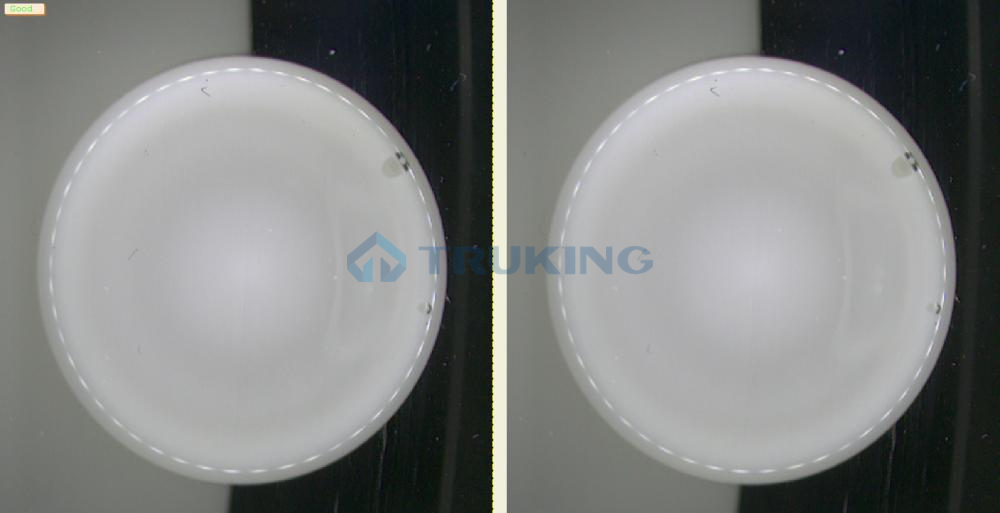

Defect Detection in Action: Visible and Accurate

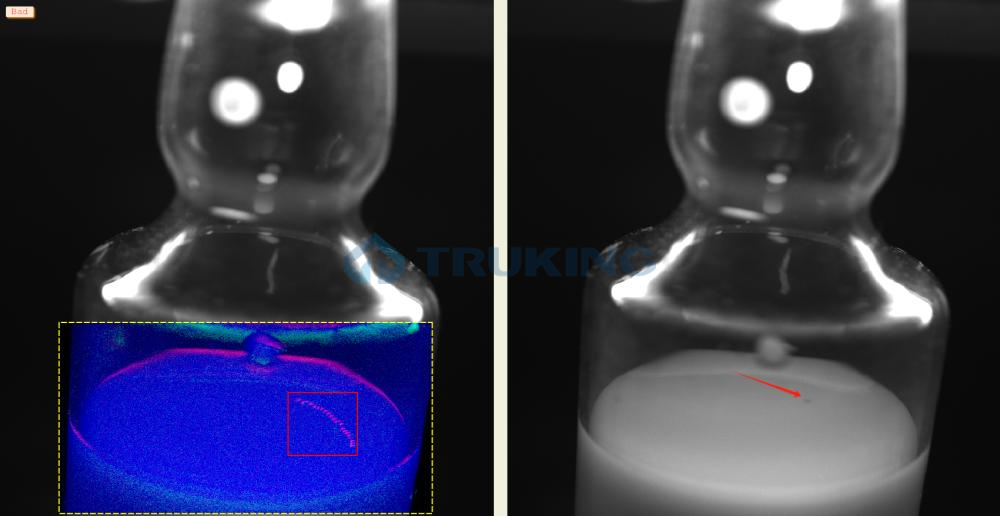

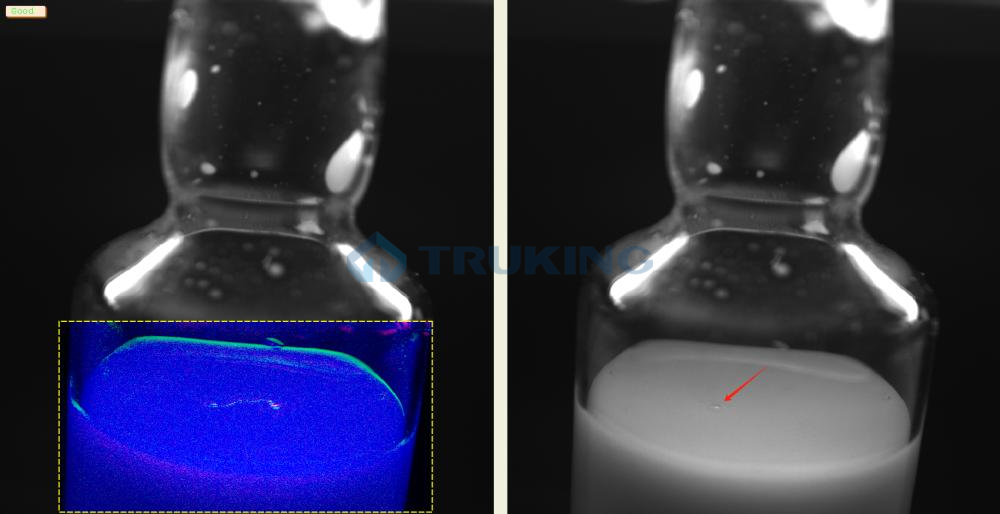

Seeing is not enough—accuracy is key. Traditional image-processing algorithms often fail to distinguish between true defects and interference from bubbles, reflections, or wall contamination, leading to misjudgments.

To address this, Truking has developed proprietary AI models that analyze movement trajectories, speed, and morphological changes to exclude most false positives.

On actual production lines, this technology has improved detection accuracy for some typical emulsion products from under 30% to over 80%.

Common Defects and Interferences in Emulsion Inspection:

Conclusion

Emulsions are widely used in critical care and anesthesia, making quality assurance vital. Their opacity and low-contrast imaging of small particles pose a widely recognized technical challenge in the industry.

Truking continues to tackle this challenge by integrating multi-source lighting, high-frame-rate imaging, and AI recognition—achieving significant results for many common defects. Acknowledging the complexity of emulsion inspection, we remain committed to further optimizing both optics and algorithms.

With a rigorous technical mindset, we continuously improve our inspection systems to ensure clearer images and more reliable decisions—fortifying the safety and quality of pharmaceutical products.