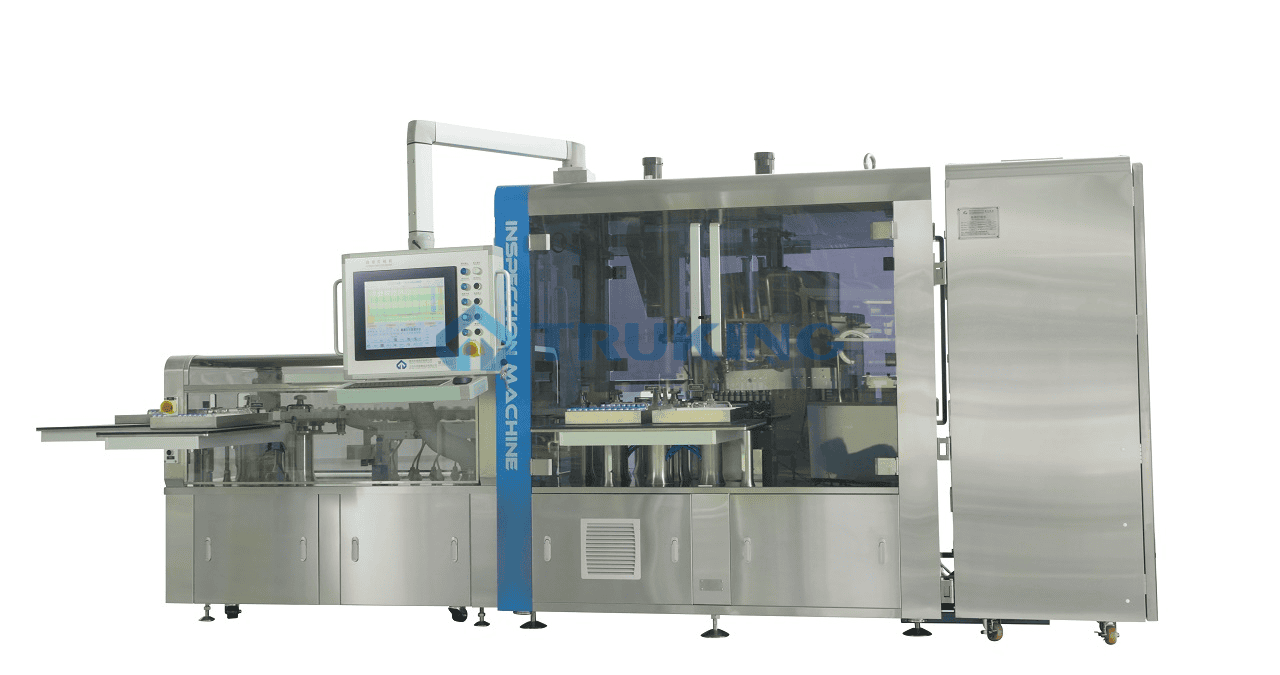

TRUKING offers excellent range of Automatic inspection machines. Our products are developed in association with our customer to match aseptic processing requirements inmost productive manner. Being a Technology leader in sterile processing TRUKING ensures its fully automatic inspection system performing in compliance with GAMP,cGMP, FDA etc.

Our innovative Inspection system are capable of catering wide range of application such as vials, Ampoules, oral-liquids etc.

Machine can be employed with fully automatic high voltage leak testing unit to inspect micro pores and to perform efficient leak detection.

Ø TRUKING with its cutting edge technology ensures right match with servo mechanical system with state of art software for excellent results.

Ø Machine employs nondestructive High voltage leak detection unit at qualified channel of inspection outfeed. High voltage leak test suitable forclosed container to check leakage up to micro pore 0.2μm.

Ø High voltage current is passed through container and variation is measured across micro pore or crack giving different receipt value of current ensuring leakage. Process is continuous and fast at high capacities.

Ø Control system of leak detection can be synchronized with inspection HMI or can be separate.

Ø Visual Inspection units are tuned at detectable precision of 40 μm as perpharmacopeia. Whole machine is designed to have zero interference from environment and no machine vibrations.

Ø Machine adopts 360° view of bottles with maximum viewing window to capture high resolution imaging on various stations.

Ø Optimized software performance to differentiate bubbles and particle with complex inspection algorithms employed.

Ø State of art system for inspection of Black particle, white particle, bottle crack, liquid level, Glass fragments and other fine impurities.

Ø Dedicated inspection of containers with cosmetic defect such has capcolor, cap scratches/logo tarnish and other sealing defects. Dedicated separate collection area for bottle with only cosmetic defects.

Ø Comprehensive study on Knapp test cut, customized product recipes controlling LED light source color, RPM rate etc.

Ø Industrial PC control with state of artfeatures for Audit trail, data integrity, Graphical debugging and remote access complying with 21 CFR Part 11 compliance.

Ø It adopts high voltage discharge detection technology, suitable for closed containers made of insulating materials. When there are holes or cracks on the insulation container, the high voltage current will enter the solution through the hole or crack, producing different current value from the intact bottle, so as to pick out the unqualified container.

Ø It adopts TRUKING independent intellectual property technology, can work separately, and also be linked with the automatic light inspection machine.

Ø Adopt servo drive system, stable and reliable operation, high degree of automation, and detection accuracy better than 0.2 μm, fully meets the testing requirements stipulated by Pharmacopoeia.