400-9988-900

400-9988-900

400-9988-900

400-9988-900

Reliable and precise packaging is critical when handling delicate pharmaceutical ampoules. Our blister cartoning machine has been developed to meet this challenge, integrating advanced forming technology, intelligent detection, and stable high-speed performance. Its key strengths can be summarized as follows:

1. Strengthened blister forming.

The machine adopts a combination of pre-punching and blow-molding, which prevents uneven forming and breakage while enhancing the overall strength of the blister. At the same time, the drawer-type installation design makes mold changes fast and efficient, reducing downtime and increasing production flexibility

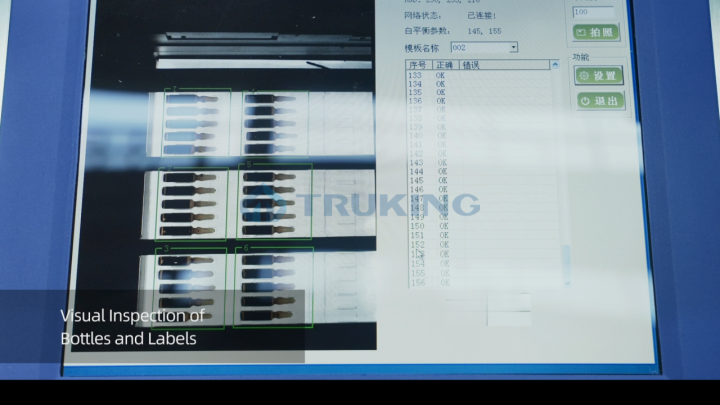

2. Intelligent visual inspection.

A built-in vision system carefully monitors the contents of each blister, detecting missing items or incorrect labeling. When an anomaly is identified, the system precisely removes only the defective unit rather than discarding the entire batch, ensuring both quality assurance and cost efficiency.

3. Automatic film alignment correction.

To guarantee accurate punching, the equipment is fitted with film-position and blister misalignment detection devices. If misalignment occurs, the dual-servo roller automatically adjusts the pulling length of the PVC film. This compensation mechanism prevents punching errors and minimizes waste during continuous production.

4. Stable carton erecting at high speed.

The cartoning stage employs a rotary carton erection device, enhanced with a vacuum pre-stretching system. This design eliminates stress on the carton board during opening and secures consistent stability, even under high-speed operating conditions.

5. Precision in the push-rod assembly.

The machine utilizes a combined push-rod structure, one for inserting leaflets and another for ampoules. By allowing the leaflet to enter first, insertion resistance is reduced, the glass ampoules are better protected, and the risk of bottles popping out is avoided. The precise positioning, low transmission damping, and servo-driven track adjustment enable the system to maintain long-term stability even during extended high-speed runs.

Together, these innovations create a packaging solution that not only strengthens product protection but also enhances operational efficiency. The blister cartoning machine reflects a commitment to advancing sterile packaging technology and delivering reliable, scalable solutions for the global pharmaceutical industry.