Truking Technology has made outstanding contribution to mass productionfor COVID-19 vaccine in the secondary packaging, and occupies an absolutelydominant market share in China.The COVID-19 vaccine is produced for 24Hcontinuously , the most important things during production are the productionefficiency,production capacity and production quality of the whole line, andalso the convenience for operation.Focus on the future,Customers is consideringenvironmental protection, intelligence and flexibility too.

Production of the whole line efficiency is over 85%

Truking technology high speed intelligentsecondary packaging lines for vials is consisting of labeling machine、 blister machine(also can choose touse paper tray instead)、cartoning machine、 laser printer and camera inspection system、checkweigher、3D-wrapping machine/Eflute cartoning machine、 track and trace system、case packer andpalletizer. The whole line can work connecting with the upstream inspectionmachine and downstream intelligent storage. Any problems with any one of theequipment will affect the customer's production. In addition to the laserprinter, check weigher, and track and trace system are for outsourcing for themoment, all the other equipment are designed and produced by Truking Technologyitself , Truking providing an overall solution for vaccine production from thewhole process of design, production, and service. The quality of the equipmentguarantor to meet 24-hour continuous production and ensure that the productionefficiency reaches more than 85%.

The whole line production speed reaches 450pcs/min

The number of drugs in a single batch, such as vaccines andmonoclonal antibodies, is about 160000 pcs. Based on the 6-hour production time(8-hour working system=6 hours of production time+2 hours of site clearance andbatch closing time), the production speed needs 444 pcs/min. The productionspeed is required for mass production, saving customer costs, and reducing therisk of production shift and batch closing. Therefore, the reasonableproduction speed of single vaccine package is 450 pcs/min, The production speedof the main equipment in the whole line is respectively - the operation speedof the labeling machine is 600 pcs/min, the blister machine is 570 pcs/min, thecartoning machine is 600 pcs/min, the wrapping machine/medium cartoning machineis 500 pcs/min, and the case packer is 8 cases/min, which fully meets thedesign speed of the whole line of 500 pcs/min, and the stable production speedof the whole line is 450 pcs/min, which already trusted by many customers,while the whole line speed of international leading enterprises is 300~400pcs/min, Truking Technology's packaging line is in a leading position in termsof capacity and delivery time.

Protect the drugs quality in all aspects

The production and storage temperature control of vaccines,monoclonal antibodies and other drugs have extremely stringent requirements.Inactivated vaccines, recombinant vaccines and insulin in new crown vaccinesrequire 2~8 ℃, and mRNA vaccinesrequire - 25 ℃~- 15 ℃.Excessive temperature will directly affect the efficacy of vaccines, which isalso the focus of vaccine manufacturers, and corresponding risks cannot betolerated.

Product inspection, batch information inspection and supervisioncode in the packaging process are all important precondition for the qualityand compliance of drug packaging. Truking Technology's whole line equipmentinspection includes the inspection of label presence, batch information camerainspection, bottle grabbing inspection, visual inspection of bottle entry,temperature inspection, dynamic compensation for blanking, detection ofnonconforming products, detection of the correctness material ofcartons,leaflet or large cases, carton weight detection, wrappingdetection,supervision code inspection and three-level association, packingquantity test, sealing tape test ,totally more than 500 quality tests, whichprovide all-round quality assurance for vaccines in the production process.

Convenient operation

In the control of quality and safetyproduction, the order of control degree is personnel- equipment -product. Itcan be seen that the most important is the control of personnel operations. Interms of bottle loading, packaging material replacement, rejected productcollection, troubleshooting, format part replacement, lack of packagingmaterial prompting and so on, Truking technologys’ equipment provides a moreconvenient way for personnel operation, with strong advantages such as non-stopreplacement of PVC, continuous production with the upstream without manualbottle loading, large space for rejected product collection, human-machineinterface fault reminder, alarm light bar prompt, whole line change partsreplacement guidance and so on, The replacement of specification parts is 50%higher than that of the previous generation products. In terms of packagingmaterial loading, Truking Technology provides an optional automatic packagingmaterial loading system to reduce operators and labor intensity.

More environmentally friendly

Truking Technology vials packaging line has the advantages ofcompatible paper tray packaging forms. The packaging materials arebiodegradable, environmentally friendly, meeting the European productstandards.

Smarter

All systems of Truking Technology meet the requirements of FDA -21 CFR part 11 and GAMP5 computerized system, such as audit trail, data backup,data integrity and other regulatory requirements

The whole line unifies the picture style, optimizes thehuman-computer interaction experience, simplifies the operation process, andgreatly improves the sense of operation experience. It has rich data managementfunctions such as OEE energy efficiency, product data and formula, and an opendata interface (OPC Ua). It can connect MES or ERP to analyze system data,centrally transmit, store, and issue production instructions.

It has the self diagnosis function of equipment faults, whichcan classify and classify faults, analyze causes and give intelligent prompts,quickly locate and deal with them in a timely manner

More flexible

Different kinds of flexible multiple transfermanipulators can be selected. The transferring or feeding magazine has lowerloading parallel manipulators, spider robots, etc., which fully meet theflexible packaging and are compatible with different kinds of products, andeasy for specification changing.

Technical demonstration of some machines

Blister machine

Reserve more space on the front of the blister machine, which canfacilitate people to collect rejected bottles or waste materials.

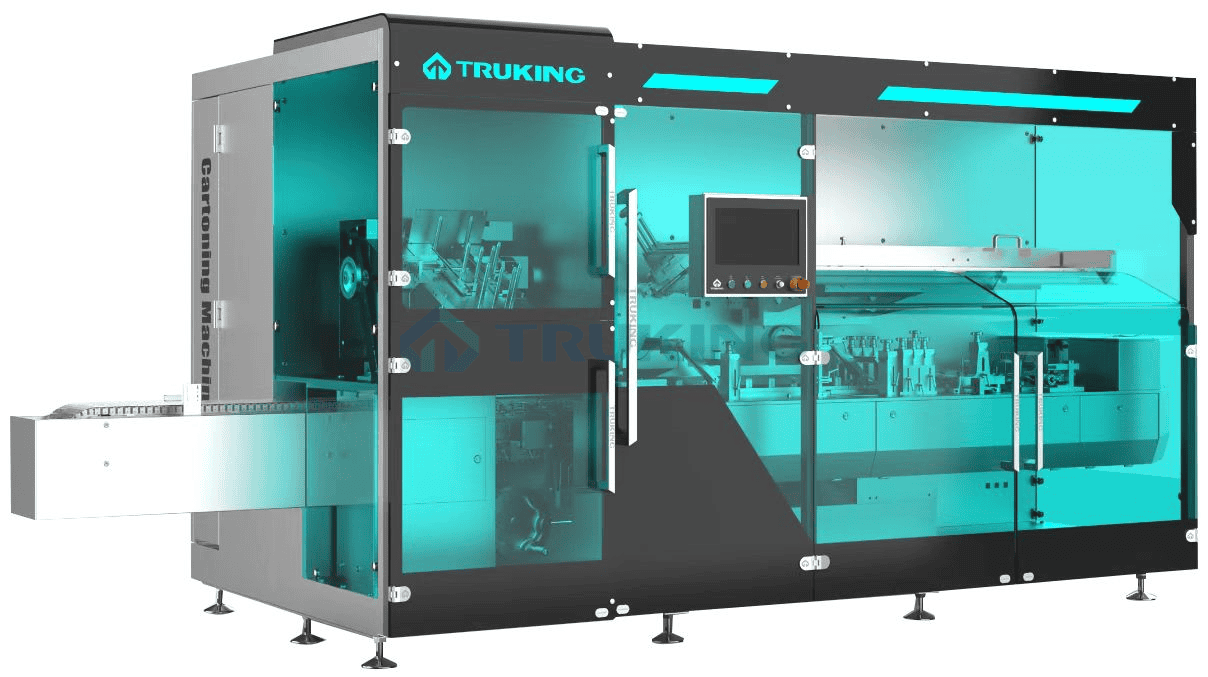

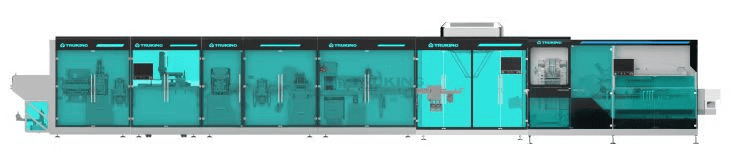

Cartoning machine