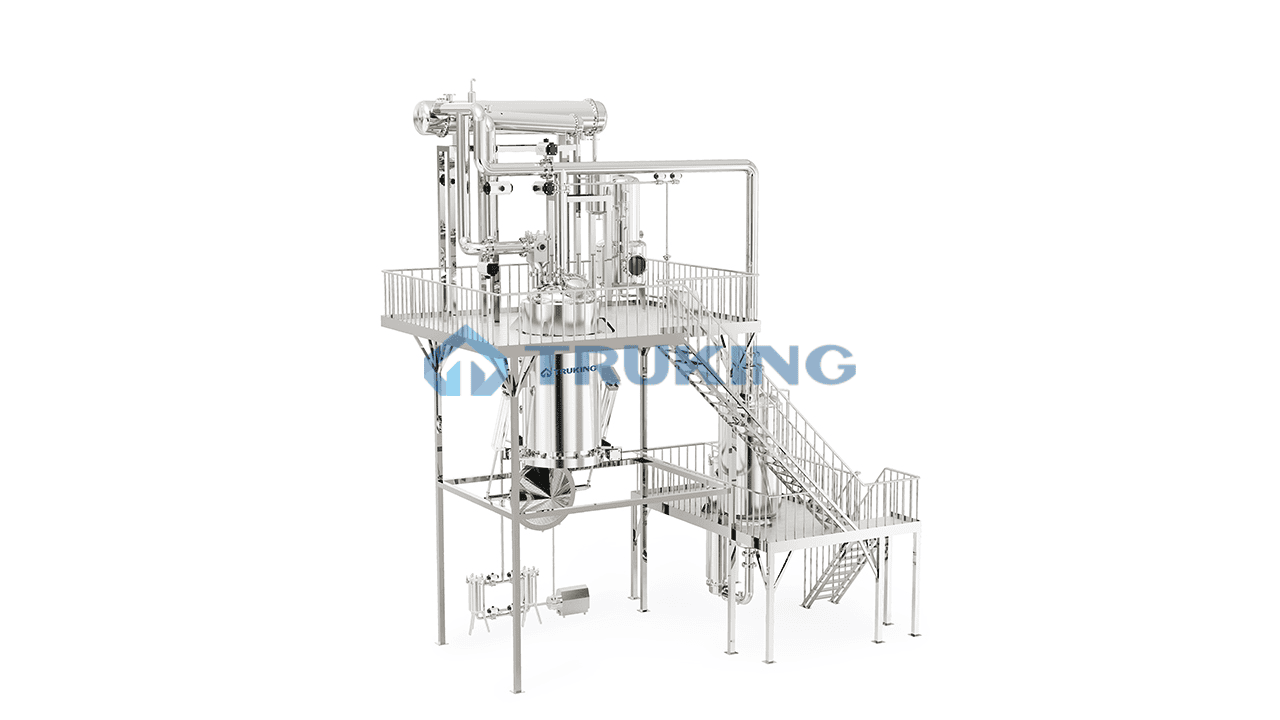

The medicinal materials are heated and extracted in the extraction tank, and the extraction liquid is filtered and enters the evaporator for concentration. The concentrated active ingredients are left in the evaporator. The difference in concentration gradient of the solvent in contact with the material in the extraction tank is increased to accelerate the dissolution rate of active ingredients in the medicinal materials. After the extraction is completed, all the concentrated liquid is retained in the evaporator. It effectively shortens the operation time of extraction and concentration, and saves the amount of solvent.

Ø Short production cycle: extraction and concentration can be carried out simultaneously. Compared with fractional extraction, it saves time for effluent, solvent addition and heat up.

Ø Less amount of solvent: Compared with fractional extraction, the hot reflux extraction process needs only to add solvent once, especially for ethanol extraction, saves a lot of solvent input and reduces production costs.

Ø High extraction efficiency: the maximum concentration difference is always maintained between the solvent and the medicinal materials in the extraction tank, which is conducive to the dissolution of active ingredients.

Ø Energy saving and consumption reduction: The energy-saving evaporator is used to concentrate the extraction liquid to save energy. The secondary steam generated by evaporation enters the extraction tank to participate in the extraction after the phase change, which reduces the consumption of steam in the extraction tank. At the same time, since only one time solvent was added, compared with the fractional extraction, the discharge of concentrated waste liquid is reduced.

Ø Controllable extraction end point: one can observe the color change of the extraction liquid through the sight glass of the extraction pipe of the extraction tank, or sample test, or use a special online detection instrument to determine the extraction end point.

Ø Simple operation: After adjusting the operating parameters, the equipment can continuously infeed and outfeed the liquid, and the automatic operation is stable, saving time and effort.

Ø Less area occupation: Compared with traditional fractional extraction, it has compact structure.

Ø Less cost: Compared with the traditional fractional extraction, the purchasing and investment cost for the intermediate storage tank can be saved.